A very special nozzle |

|

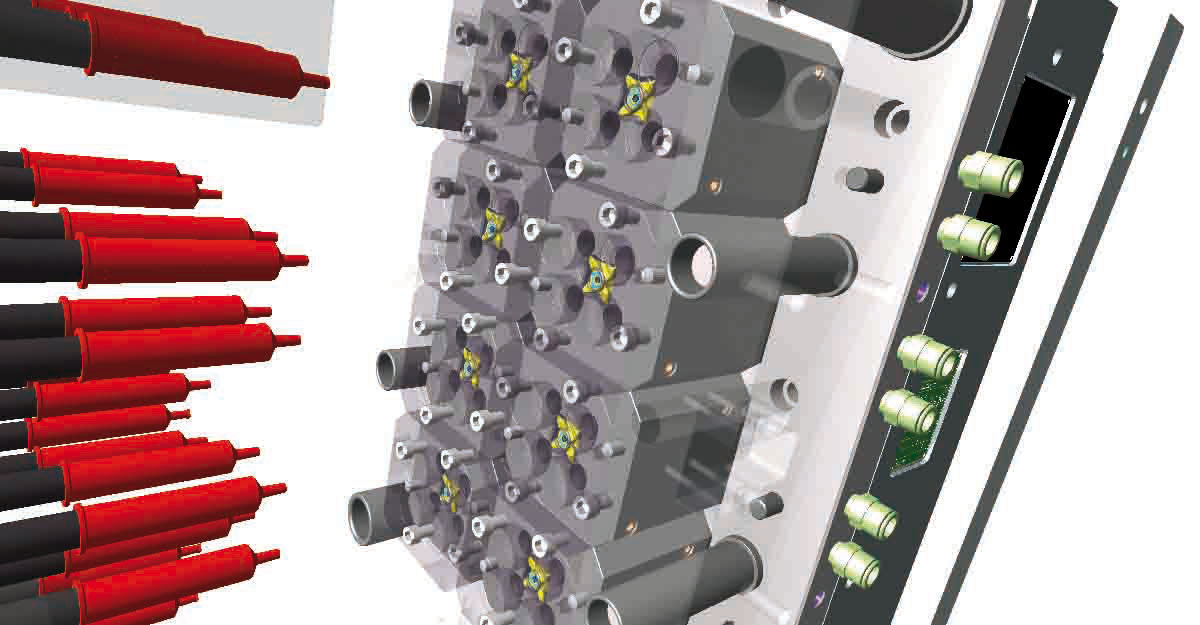

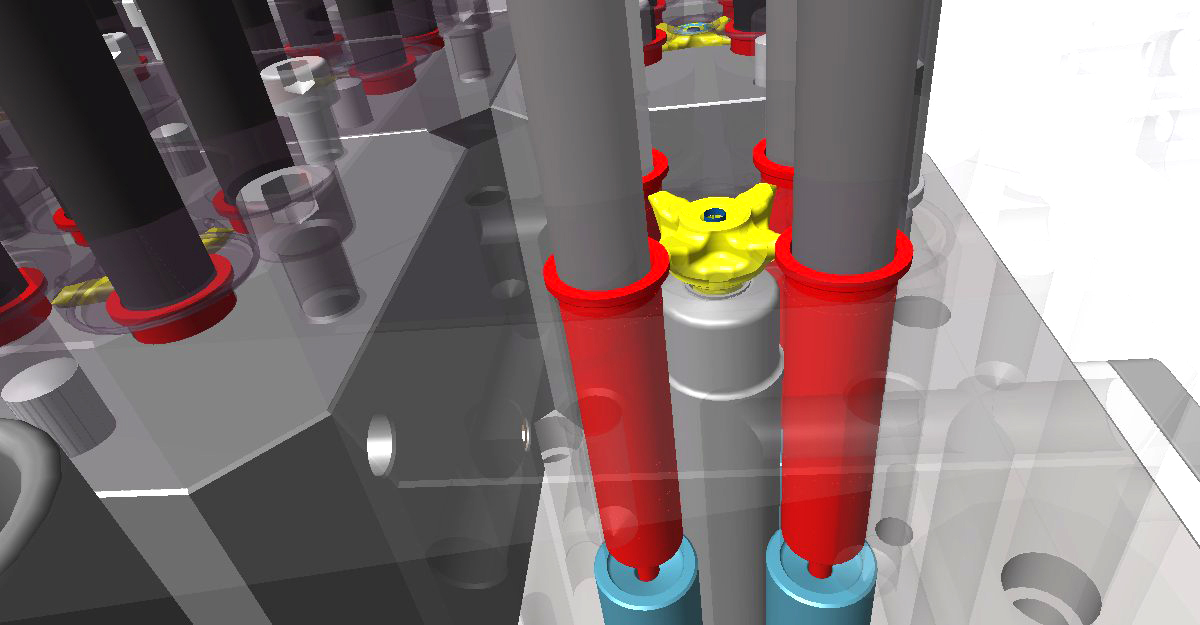

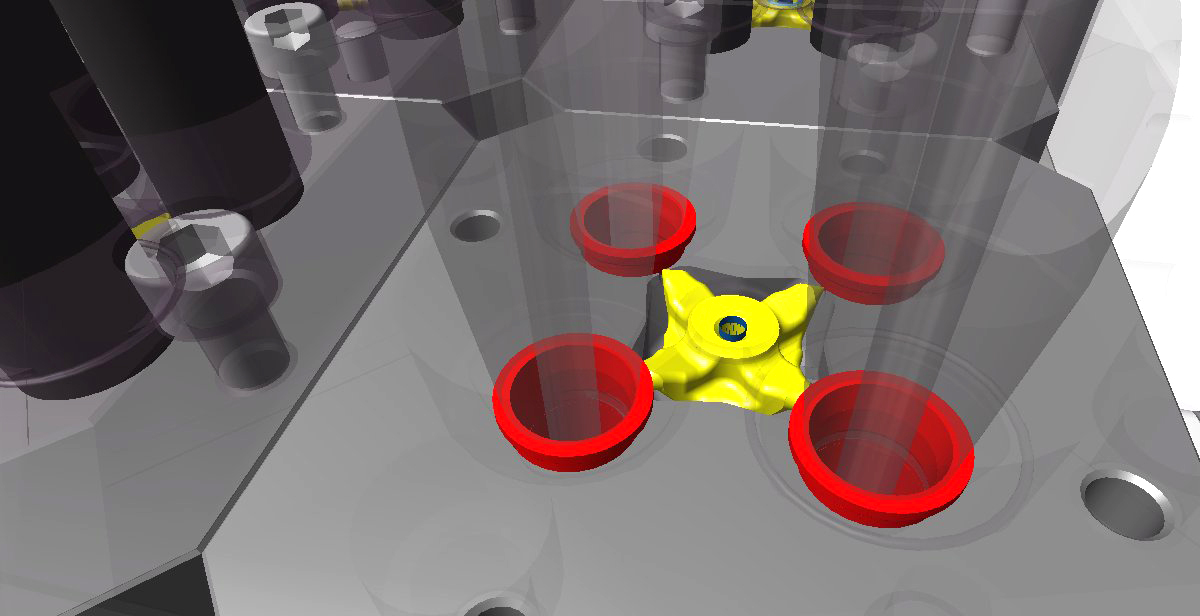

The nozzle made by Thermoplay allows the elimination of traditional "tunnel" sprues, used in such applications, being the injection direct on the annular wall of the cavity. The combination of elements constituting the nozzle allows to optimally control the temperature and to balance the injection of material into the cavity, so minimizing the inflections and expansion of the material and reducing the movement of the male into the cavity; also ensuring a further advantage of cleaning on the machine board and easy maintenance of the cavity, that can be done fast without removing the mold from the press, as often requirement by many mold makers. It also becomes easier making the seat of the mold and the double seal on the nozzle is a guarantee of no material leakage. The significant thermal profile of the nozzle and the insulation of the tip from the forming matrix, allow to use process parameters aligned with the ones suggested by the plastic material manufacturers. |

|

|

|

Here is some information on the application: The cylindrical body of the 5 ml syringe made by Abazia weighs 2.7 grams, has an average thickness of 0.8 mm and it is in polypropylene “Medical Borealis”. Every part is produced in a cycle time of 8 seconds with 150 tons press and a 32 cavity mold of dimensions 446 x 396 x 470 mm. Injection molding is performed by n.8 Thermoplay special nozzles for syringe with 4 injection points and a control unit Thermoplay TH-M6 with 12 zones. |

|

|

|

| THERMOPLAY S.p.A - Via Carlo Viola, 74 - 11026 - Pont Saint Martin (AO) Italy - tel. +39 0125 800311 r.a. - fax +39 0125 806271 - 805567 - thermoplay@thermoplay.com |