|

|

The best for injection molding |

Thermoplay presented at K2019 show its new range of hot runner systems for multi cavity molds up to 144 cavities. The new “TD” series is provided with an external bushing having a double sealing on the external surface that prevents from leakage and provide better insulation. The external sealing requires lower precision on the mold design and manufacturing, facilitating the mold making operations. The catalog pages and the seats designs of new TF and TD nozzles are available in the Catalog section of our website, and replace the FN / FT and DN types, which will be available only for diameters 32, 44 and 46. |

|

The manifolds design and construction has been improved to suit better multicavity molds applications. The manifold has been provided with screws fixing the manifold on the mold plate, to avoid possible leakages. |

|

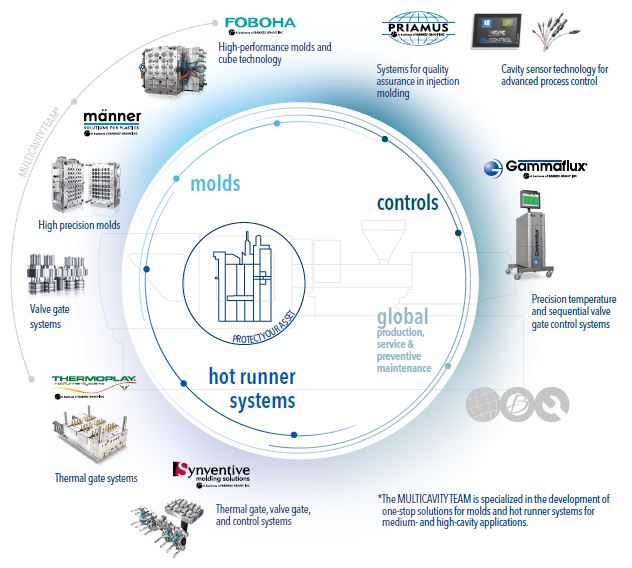

Barnes Molding Solutions The expertise and know-how achieved during last years allow to offer innovative solutions for demanding projects concerning the manufacture of plastic parts in the medical/pharmaceutical, personal care, packaging, automotive and technical parts markets, as well as electrical and household applications. Molding Solutions’ strategy ensures that each brand of the company focuses on the development of its core competencies while close cooperation between the brands provides the customer with the best solution for the respective application. |

|

|

Männer, FOBOHA, and Thermoplay represent the multicavity team within the Barnes Molding Solutions strategic business unit, serving the market for medium- and high-cavity applications. The key strength of these three multicavity experts is several decades of experience with molds and hot runner technology as well as knowledge about their technical interaction. In addition, the hot runner division benefits from the extensive application knowledge of the moldmakers, which allows them to recommend the optimal hot runner design solutions to customers. |

THERMOPLAY S.p.A. |