Barnes Molding Solutions at K show

For the first time we will be jointly exhibiting at the 2019 K trade show with the complete Barnes Moldings Solutions strategic business unit at a booth in the new Hall 1 C50 and E50.

FOBOHA, Gammaflux, männer, Priamus, Synventive and Thermoplay are each a recognized expert in their field. Together we are the Barnes Molding Solutions strategic business unit and combine mold and hot runner technology, temperature and process control into a tailor-made overall solution.

Stop by our booth, our team is looking forward to your visit!

Our Show Highlights

&

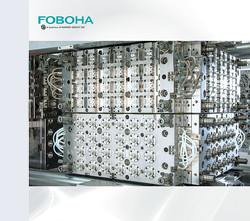

&FOBOHA

introduces innovative mold concepts: the “Compactcube,” a Plug ‘n Play® cube for rapid implementation and easy maintenance. FOBOHA will also give live demonstrations of its Reversecube solution that features counter-rotating cubes take the place of several injection molding machines and automated assembly units with a single system.

Gammaflux

is presenting several integrated solutions in its G24 temperature controller: a hydraulic power unit for activating the hydraulic valve gate systems and an integrated sequential valve gate control (SVGC). A second system integrates the männer e-control, a servo-electric controller for valve gate systems. In cooperation with Priamus, the Q-Monitor (quality assurance through monitoring) is integrated within the G24 controller.

Priamus

supplies quality assurance solutions for the injection molding process. The control technology pioneer ensures optimum process control with its FILLCONTROL and state-of-the-art sensor elements. With its Quality Monitor, Priamus is also presenting a production-optimized solution for process monitoring.

Synventive

is presenting the latest generation of its eGate® system for the first time at a European trade fair. The electric-drive valve gate solution is now also available for larger components. This ensures complete pin movement control at each individual nozzle for highest performance, flawless surfaces and outstanding part-to-part consistency. A live demonstration of the proven SynFlow® two-speed pin control technology will also be available. Synflow® for hydraulic cascade molding now offers even more melt flow functionality and features a new interactive user interface.

Reliability and cost-effectiveness in production

Männer, FOBOHA and Thermoplay represent the multicavity team within the Barnes Molding Solutions strategic business unit serving the market for medium- and high-cavity applications. The key strength of the three multicavity experts are their many years of experience with both technologies ‒ molds and hot runner technology ‒ and knowledge about how the two technologies interact.

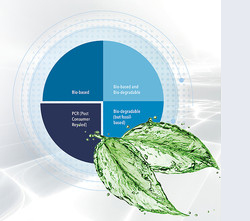

Environmentally friendly plastics

A central topic in the processing of biopolymers and recycled materials is process control. By working together with Gammaflux, the expert in temperature control systems, and Priamus, a pioneer in advanced process control systems, we are able to safely process many recycled bio-based and/or biodegradable materials. We will present our extensive material test collection as well as implemented customer projects at the 2019 “K” – the world’s foremost trade fair for plastics and rubber.

- RELIABLE SOLUTIONS

- SOLUTIONS FOR AESTHETIC PARTS

- ADVANCED TECHNOLOGIES FOR HIGH QUALITY AUTOMOTIVE PARTS

- SOLUTIONS FOR SMART CLOSURES

- SOLUTIONS FOR HIGH SPEED MOLDS

- SOLUTIONS FOR POWERFUL COMPONENTS

- TEMPERATURE AND PROCESS CONTROL.

- SOLUTIONS FOR FUTURE GENERATIONS

- EFFICIENT CUBE TECHNOLOGY IN XS SIZES

- CUBES FOR MORE OUTPUT, SHORTER CYCLE TIME, LESS SPACE

... and much more! Come see for yourself.

Extensive information is available here during the show.