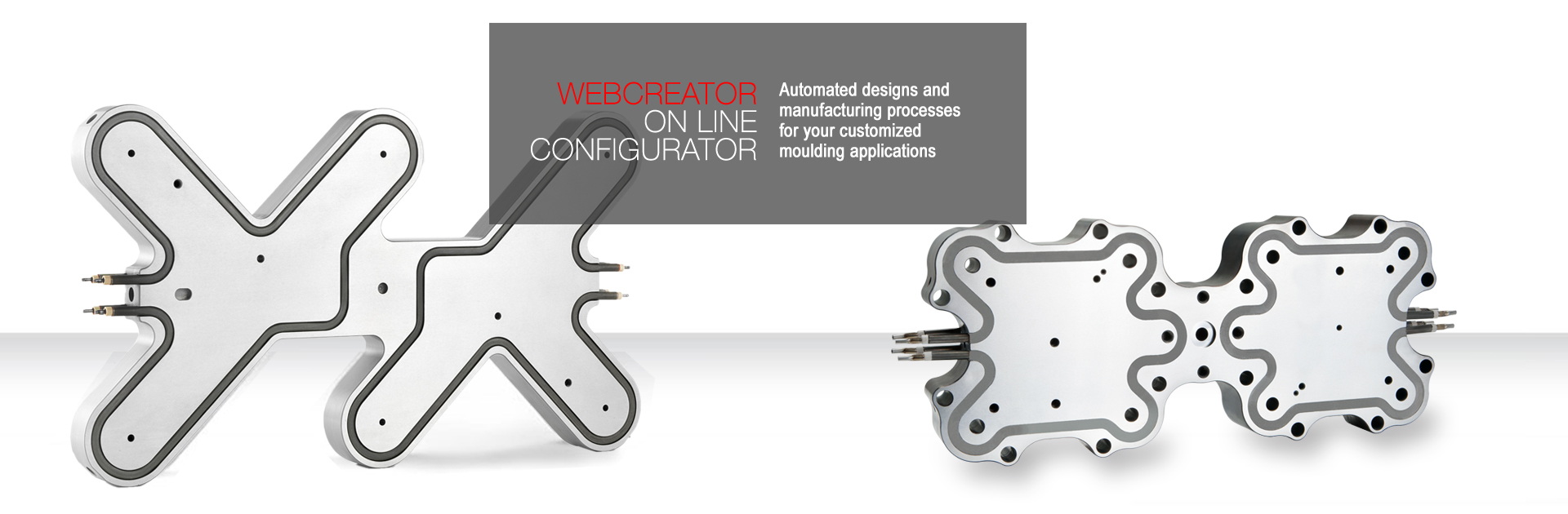

Webcreator

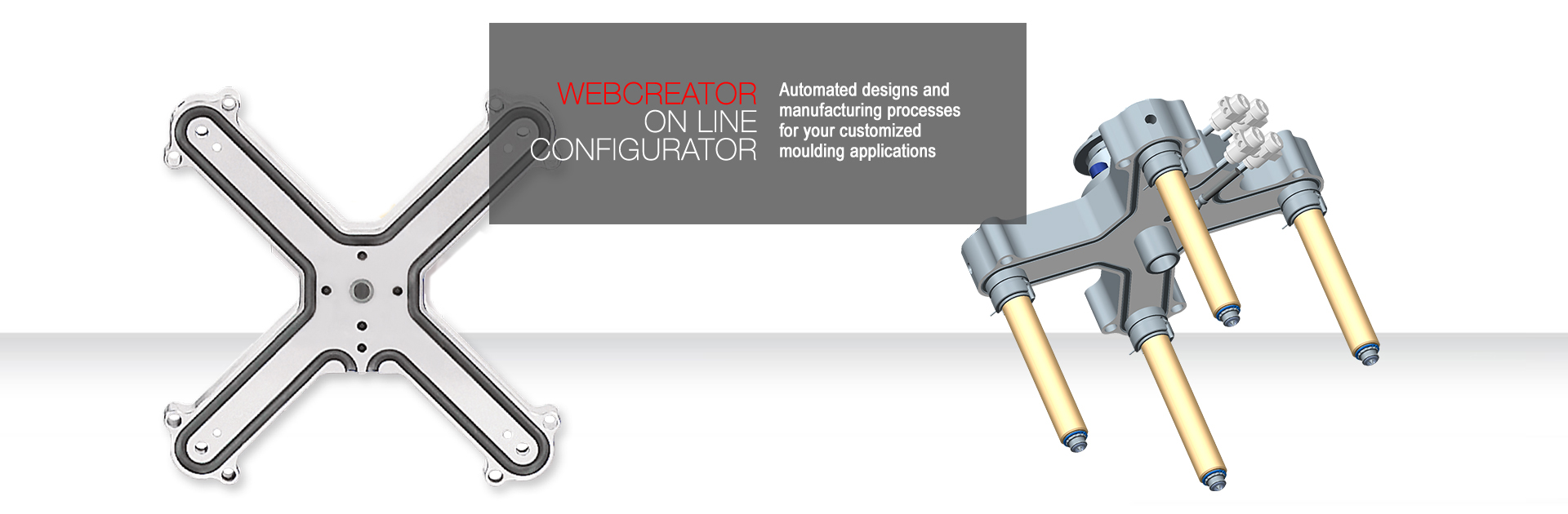

WEBCREATOR is a web-based design application for configuring Thermoplay Hot Runner Systems with standard nozzles and accessories. This generates high quality CAD 2D and 3D models reducing the production time.

The hot runner system is freely configured in relation to the distance between the nozzles and accounts for the polymer processing conditions. The diameter of the manifold channels, as well as of the descent holes to the nozzles and the injection bushing size are configured to suit.

After configuration the 2D drawings and 3D models are generated in the selected format and sent by email to the user in a single zipped file, which also includes the configuration sheet and part list (in pdf format).

Any configurations made can be modified to generate a new drawing later. WEBCREATOR does not perform any check on the configured system in relation to the injected polymer.

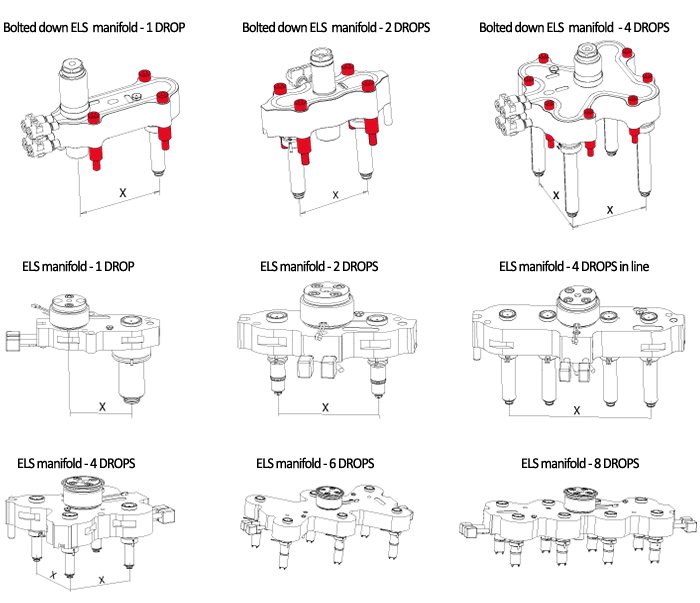

There are 2 types of configurable manifolds.

The ELS series, with standard nozzles and accessories, has the option of 1, 2, 4, 6 and 8 drops.

The main features of this system are:

- Distance between axis of manifolds is freely configurable.

- Construction of the manifold can be with or without a “heater cover” depending on the injected material and the transformation temperatures.

- Flow channels are sized according to the type and diameter of the nozzle chosen.

- Nozzle and injection bushing can be chosen throughout the standard range.

- Choice of any valve gate groups within the standard Thermoplay range; choice of pin finishing.

- Option to include zones identification plate on the system.

- Thermocouples are J type and can be insulated or grounded.

Bolted down ELS manifolds

The bolted down manifolds are available with or without heater covers, and can be configured with TF12 – TF17 – TF23 and TD18 nozzles. They are available only with heater covers for the TD22 nozzles.

The Webcreator allows to configure bolted down injection systems with 1, 2 and 4 nozzles. Configurations over 4 nozzles are possible only on demand as special systems.

The pressure pads located between manifold and back plate, have been eliminated in the bolted down systems, with the following benefits:

- improved safety against the risk of leakages due to wrong process parameters (cold starts, interruption of the cooling system in the hot half plates).

- decreasing of power consumption.

- eliminate the transfer of mechanical stresses from the injection system to the mould.

- more homogeneous temperature distribution in the hot half plates.

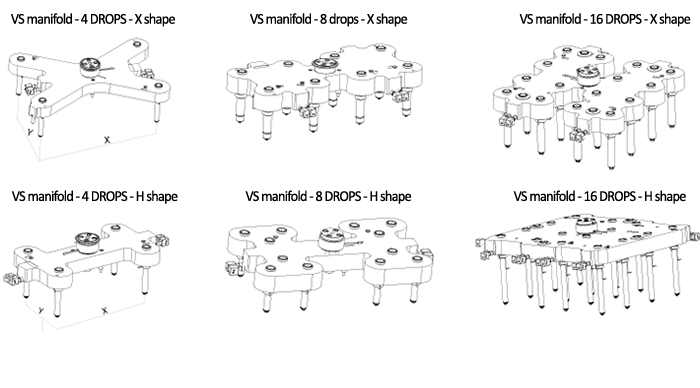

The VS series injection systems differs from ELS system for the following characteristics:

- Can be an ‘X’ or ‘H’ shape manifold.

- Available up to 16 drops.

- Only suitable with coverheater.